When it comes to vehicle maintenance, understanding alternator wiring connections is crucial for ensuring proper functionality of the electrical system. Alternator wiring connections play a key role in charging the battery and powering various components of the vehicle. Without proper wiring connections, the alternator may not function correctly, leading to issues such as a dead battery or electrical failures.

Why are Alternator Wiring Connections Essential?

Proper alternator wiring connections are essential for the following reasons:

- Ensuring the alternator charges the battery effectively

- Providing power to the electrical components of the vehicle

- Preventing electrical malfunctions and failures

How to Read and Interpret Alternator Wiring Connections

Reading and interpreting alternator wiring connections can be daunting for those who are not familiar with electrical systems. Here are some tips to help you understand alternator wiring connections:

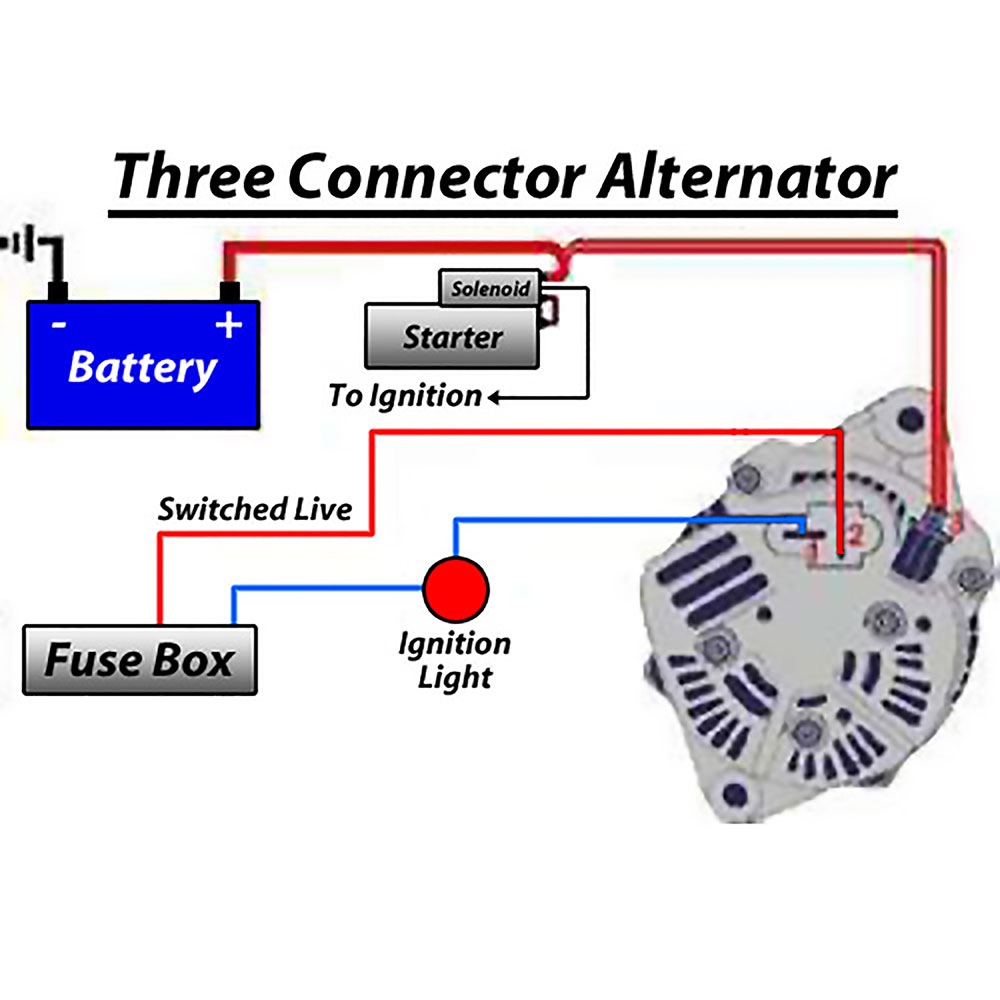

- Refer to the vehicle’s wiring diagram for guidance

- Identify the different wires connected to the alternator and their functions

- Check for any signs of damage or wear on the wiring connections

Using Alternator Wiring Connections for Troubleshooting

Alternator wiring connections can be used to troubleshoot electrical problems in the vehicle. By inspecting the wiring connections, you can identify issues such as loose connections, frayed wires, or corroded terminals. Troubleshooting alternator wiring connections can help diagnose and fix electrical problems before they escalate.

Importance of Safety

When working with electrical systems and wiring diagrams, it is essential to prioritize safety. Here are some safety tips and best practices to keep in mind:

- Always disconnect the battery before working on the electrical system

- Use insulated tools to prevent electric shocks

- Avoid working on the electrical system in wet or damp conditions

- Consult a professional if you are unsure about any wiring connections

Alternator Wiring Connections

Common Delco SI Series Alternator Wiring Diagram | Smith Co Electric

24 Volt Alternator Wiring Diagram

Bosch 24v Alternator Wiring Diagram – Wiring Diagram

Powermaster Alternator Wiring Diagram

[18+] How To Wire A Chevrolet Alternator, Vehicle Alternator Wiring Diagram

![Alternator Wiring Connections [18+] How To Wire A Chevrolet Alternator, Vehicle Alternator Wiring Diagram](https://i1.wp.com/i.pinimg.com/736x/88/5b/81/885b81e7558a8eb81806bc92ee85e97e.jpg)

Alternator Wiring – Electrics – RHOCAR – The UK Kit Car Club